Extrusion may be defined as a process for making a product an extrudate by forcing a material through an orifice or die to form a shape or alternatively the production of finished or semi-finished products using an extruder. Temperature that will maximize the coefficient of friction at the barrel wall there in turn maximizing the solids conveying of the resin.

Pin On Jwell Profile Extrusion Machine

A higher extrusion temperature results in a higher MFR 37 caused by more chain scission.

. Understanding the extrusion temperature of aluminum profile. PP - Polypropylene Extruder. The melt is extruded through a circular die to produce a highly puffed rope which is cut to the desired size by a revolving blade.

Introducing the details of the instrument. Material should be cheesy at the vent. A Du Pont nylon extrusion study noted that exit-melt-pressure fluctuations were seven times more extreme after the temperature of the two rear zones was dropped 50 deg F.

Hence this temperature pro le brings a material temperature in the die of 195 C in the case of PLAPA11 blends and 226 C in the case of PLAPA6 blends. Setting the center and front zones. Increasing the melt temperature from 455 to 509F 235265C decreases the viscosity by 26 times.

440500 227260 Polycarbonate melt viscosity is more temperature-sensitive than shear-sensitive. 200-250C 392-482F Melt Temperature. Even thin core projections can be cooled by bubblers.

Download Table Extrusion temperature profiles for each polymer. A Mobay processing handbook indicates that a 10-deg-F change in a 390F rear barrel zone can affect screw power by as much as 20 percent in extru sion of Texin 355D polyurethane. Samples of each formulation were collected after the first third and fifth extrusions.

PE-LD - Low-density polyethylene Extruder. This is meant as a general guide. The goal is to have the front zone at the same temperature as the melt coming out of the metering zone.

Where straight-through cross-bored holes are applicable their diameters should be 05 inches and spaced on 15 to 2 inch centers. Long cores should be controlled by bubblers. Deterioration in the Physico-Mechanical and Thermal Properties of Biopolymers Due to Reprocessing Biopolymers.

Barrier Screw 25-30 LD Compression Ratio. Single Screw with vacuum grooved feeding section Screw Design. Mold temperature control Water channels must be located in both halves of the mold.

If the front zone temperature is different there will be a problem with melt uniformity. For most polyolefin resins Zone 1 should be set between 300F and 400F. Aluminium Profile for Wardrobe.

The selected temperature profile was based on typical PP. 170-200C 338-392F Melt Temperature. Slip additivated PE-LD as blend.

Barrier Screw 25 - 30 LD Compression Ratio. 41 Melt flow and temperature profile in extrusion Extruder converts polymer materials from solid to molten state by using the frictional heating as well as the external heat source. Extrusion temperature profile The blend was either pelletized on a Modern Plastics Machinery 1 extruder at 500F or 550F for 1 2 3 4 and 5 extrusions.

Aluminum Tube and Pipe. The higher the final recommended. The process parameters and technical limits are determined by the properties of.

To achieve melt uniformity these are both set at the target melt temperature 485 F 250 C. Extrusion temperature is typically 160180C and the compression ratio is 21 or less. Increasing the shear rate from 100 to 400 sec 1 over the same temperature range reduces the viscosity 15 times.

Specialized in manufacturing aluminum profilesaluminum extrusion profiles products since 2003. Single Screw Extruder with vacuum grooved feeding section Screw Design. View in full-text Context 2.

No 3 hours at 80C 176F for regrind Calibration.

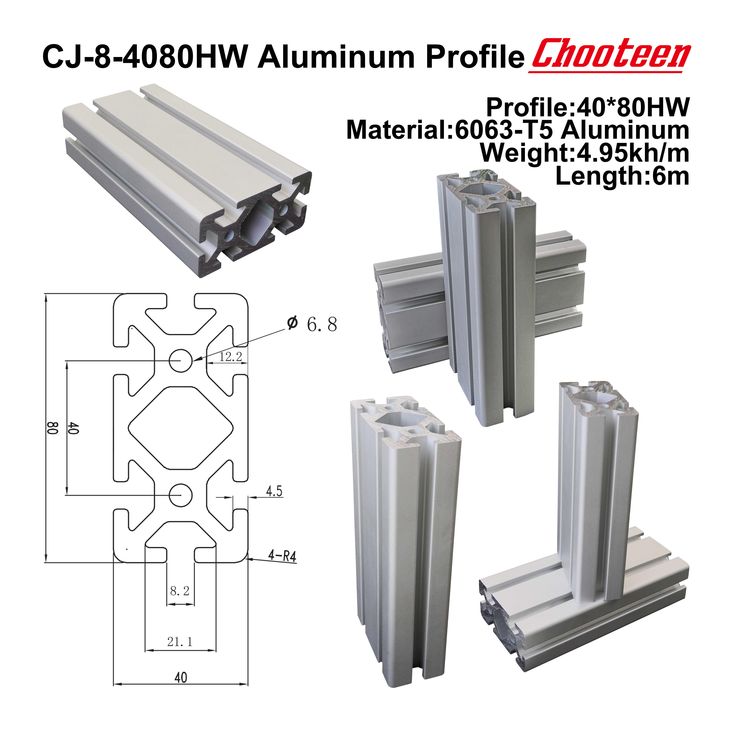

T Slot 4080 Aluminum Profile Aluminum Extrusion Aluminum Shelves Extrusion

6063 Anodized Aluminum V Slot Extrusion Aluminum Profiles Aluminum Extrusion Extrusion Aluminum Railing

4080b Aluminum Profile Aluminum Shelves Aluminum Extrusion Extruded Aluminum

Guarantee Promise 5050 Aluminum Extrusion Profile Aluminum Extrusion Aluminum Shelves Extrusion

40x80 4080 T Slot Aluminium Extrusions Profiles Aluminum Extrusion Extrusion Extruded Aluminum

6063 T Slot 2020 Dimensions Aluminum Extrusion Profile Cover Slot Aluminum Extrusion Extrusion Aluminum

4545 Aluminum Extrusion Profile Aluminum Extrusion Extrusion Aluminum Shelves

Source Scaratch Resistance Sandblasting Anodized 6063 Extruded Scaffolding 4080 Housing Aluminum Extrusion Profi Aluminum Extrusion Extrusion Extruded Aluminum

Powder Coating Aluminum Extrusion Powder Coating Powder Coating Aluminum

4080 T Slot Aluminum Profile Aluminum Extrusion Aluminum Shelves Extruded Aluminum

Pin On Aluminum Profile Extrusion

Mill Finished Or Natural Anodized Aluminium Extrusion Profile 2040 For Construction

T Slot 45x45 Bosch 8mm T Slot Aluminum Extrusion Profile 4545 Aluminum Extrusion Extrusion Extruded Aluminum

10x 2020 Cast Aluminium Extrusion Profile V Slot 90 Degree Right Angle L Shape Ebay In 2022 Aluminum Extrusion Extrusion L Shape

Aluminium 2020 T Slot Channel Profile V Slot Supplies Aluminum Extrusion Extruded Aluminum Extrusion

Industrial Silver Anodized Aluminum Profile 80160 T Slot Aluminum Extrusion Aluminum Extrusion Extrusion Extruded Aluminum

Alloy 6063 T5 Anodized Aluminum Extrusion 3060 T Slot Industrial Aluminum Profile Aluminum Extrusion Extrusion Aluminum

Aluminium Extrusion Handling System Aluminium Profile Cooling Table Aluminum Extrusion Extrusion Aluminium

Square Structure V Slot Industrial 4040 8080 Aluminum Profile Extrusion For Factory Workbench Aluminum Extrusion Extrusion Extruded Aluminum